1. Introduction to the Project

1.1 Project Background

1.1.1 Product Introduction

PLA, short for Poly Lactic Acid, is a new biodegradable material, which is a polymer formed by dehydration condensation of starch. It has good biodegradability, can be completely degraded by microorganisms in nature after use and finally generates carbon dioxide and water, without pollution to the environment and harm to greenhouse effect, which is very beneficial to environmental protection and is recognized as an environment-friendly material. At present, PLA has a wide range of uses and can be used as packaging materials, fibers, nonwovens, etc.

1.1.2 Market Prospect

Polylactic acid, also known as polylactide, belongs to the polyester family. Polylactic acid is a polymer obtained by polymerization with lactic acid as the main raw material. The raw material source is sufficient and can be regenerated, mainly using corn, cassava and other raw materials. The production process of polylactic acid is pollution-free, and the product can be biodegraded to realize circulation in nature, so it is an ideal green polymer material.

Polylactic acid has good thermal stability, with processing temperature from 170℃ to 230℃ and good solvent resistance. It can be processed in various ways, such as extrusion, spinning, biaxial stretching and injection blow molding. The product made from polylactic acid can not only be biodegradable, with good biocompatibility, glossiness, transparency, hand feeling and heat resistance, but also has certain bacteria resistance, flame retardancy and ultraviolet resistance. Therefore, it has a wide range of applications and can be used as packaging materials, fibers and nonwovens. At present, it is mainly used in the fields of clothing (underwear, outerwear), industry (construction, agriculture, forestry, paper making), medical and health care, etc.

Seeing the increasingly prosperous application prospect of PLA as a new biological material, some corn deep-processing enterprises and biochemical engineering enterprises in China began to invest in the PLA industry. With the establishment of PLA production lines at Zhejiang Hisun Biomaterials Co., Ltd. and Jilin COFCO Biomaterials Co., Ltd. in late 2018, the annual designed production capacity of PLA in China was nearly 130,000 tons in 2018. In 2019, the production capacity was about 149,000 tons and the output was around 139,000 tons.

PLA coated paper is made of 100% corn plastic with PLA raw material and does not use any additives. 100% PLA raw material is coated on the paper. PLA coated paper is not only composed of biological matrix and renewable raw materials, but also has similar characteristics to the existing PE coated paper molding and processing technology. Made of 100% natural biomass, it will not release peculiar smell and toxins when in use, and the temperature resistance can reach 100℃.

PLA coated paper is a new material with 100% natural, non-toxic, environment-friendly and sustainable concepts. It heats PLA environmental protection materials into liquid form and then evenly coats them on cardboard to be used in the production and manufacture of various waterproof and oil-proof food packaging paper containers, such as water cups, soup cups, bowls, lunch boxes, etc. PLA, also known as polylactic acid, is an environmental protection material, a biodegradable and compostable thermoplastic material, and takes plants as the main raw material source. The 100% completely biodegradable material formed by extraction, fermentation and polymerization can be completely decomposed into carbon dioxide and water required for plant growth by microorganisms in composting environment. Due to the compostable characteristics of the paper itself, PLA coated paper itself is a 100% decomposable and compostable environmental protection and health product, which conforms to the certification of food accessible and compostable in major markets in the world, including BPI certification in the United States, JBPA certification in Japan and OK Compost certification in Europe.

Compared with traditional PE coated paper products, PLA coated paper products can recycle used packages or containers. For contaminated recycled products, incineration, burial or composting can be used. The utilization of renewable resources and diversified recycling methods greatly reduce the burden of products on large natural resources and the environment. It also symbolizes that PLA coated paper is taken from nature and returns to nature, which conforms to the principle of endless green circulation.

With the continuous deepening of environmental protection in the world, the Paris Agreement framework will be implemented by 2020, and the global food packaging materials will be completely banned. PLA is the most important raw material to replace traditional plastics. In recent years, European countries have legislated in the food industry that PLA must be used for food packaging materials. Europe and North America are PLA’s major markets, while the Asia-Pacific region is one of the fast-growing markets. Due to smog and even global changes in environmental climate, China pays more attention to environmental protection issues. Disposable paper products are more easily decomposed by the earth’s natural environment than disposable PS, PP or PE, thus reducing the pollution caused by petrochemical products to the earth’s environment. In China’s economic development planning, environmental protection industry has been incorporated into key projects, with special support and guidance for projects. The Northeast market has great potential. Considering the material transportation costs and other factors, such as the development of this project in the Northeast, it can cover the food packaging and green packaging of the packaging industry in the whole Northeast region, and has positive effects on the ecological environment and economy in the Northeast.

China's market demand for PLA was about 160,000-180,000 tons in 2019, which is expected to expand by 15% - 25%. Today, the major consumption field of PLA is packaging materials, accounting for about 65% of the total consumption, followed by biomedicine field, accounting for about 26% of the total. China is one of the markets showing the fastest growing demand for PLA. With the market expanding, China's demand for PLA will keep growing.

In China, enterprises that produce PLA are mainly Nantong Jiuding Biology Engineering Co., Ltd, Hisun Biomaterials Co., Ltd, Shenzhen Esun Industrial Co., Ltd. and others. The annual production capacity was about 46,000 tons, which was not high. The demand quantity reached 2.65 million tons (It is estimated that there will be 5.33 million tons in 2020).

To sum up, PLA has a large market demand at home and abroad and the development space for materials of PLA in the fields of food packaging, medical treatment, packaging industry and agriculture is unlimited.

1.1.3 Technical Analysis

In this project, PLA is produced by direct polycondensation of lactic acid, and then PLA materials are compounded with paper to form paper containers. The core of the technology is that chemicals such as glue cannot be added in the compounding process, and only the characteristics of the material itself can be used for compounding.

1.1.4 Advantageous Conditions of Project Construction

(1) Policy advantage

Made in China 2025 requires that we should pay close attention to the impact of subversive new materials on traditional materials, conduct the early layout and development of strategic frontier materials such as superconducting materials, nanomaterials, graphene and bio-based materials, and speed up the upgrading of basic materials.

The State Council issued the “13th Five-Year” Plan for the Development of National Strategic Emerging Industries and proposed that by 2020, efforts should be made to bring a number of new material varieties into the global supply chain, with the self-sufficiency rate of major key materials reaching more than 70%, initially realizing China’s strategic transformation from a big country to a strong country in materials.

The Ministry of Industry and Information Technology and the Ministry of Finance jointly issued the Notice on Printing and Issuing the Construction Plan of the National New Materials Industry Resource Sharing Platform and proposed the following development goals: by 2020, it is intended to center on key areas such as advanced basic materials, key strategic materials and cutting-edge new materials and key links in the new materials industry chain to basically form a sharing service ecosystem for new materials industry resource with multi-party co-construction, public welfare as the main and efficient integration.

Jilin Economic and Technological Development Zone is a national development zone and an agency of the municipal government. It enjoys the management authority of the national development zone in terms of project approval and other aspects, and implements a “nanny, running and precise” service system for enterprises. The government affairs hall of the development zone is equipped with service windows such as project initiation, planning and construction, land, environmental protection, safety, technical supervision, public security and fire-fighting, industry and commerce, taxation, banking, etc. to provide customers with all-round, whole-process and all-weather “one-stop” quality services.

(2) Industrial advantage

Jilin City is an old industrial base that China has focused on during the “First Five-Year Plan” period. After years of development, especially more than 30 years of reform and opening up, traditional industrial systems such as petrochemical, automobile, metallurgy, energy, agricultural product processing and nonmetallic minerals have been formed, and new industrial systems such as carbon fiber, equipment manufacturing, biological industry, basic electronics and power electronics have been formed. PetroChina Jilin Petrochemical Company, Jilin Fuel Ethanol Company and Jilin Chemical Fiber Group Company occupy important positions in the same industry in China.

The regional environmental impact assessment of Jilin Economic Development Zone has been approved by the provincial environmental protection department as early as possible, and is one of the few regions in the province with the qualification and ability to undertake chemical projects. The public works and infrastructure in Jilin Economic Development Zone are improving day by day, and the planning area has already realized “nine connections and one leveling”. Currently, there is one primary substation and 3 secondary substations, which can provide 66 kV and 10 kV power supplies. It can supply 80,000 tons of domestic water, 114,000 tons of industrial water, 360,000 tons of sewage treatment, 550 tons of steam supply capacity per hour, high, medium and low pressure industrial steam under 38 kilograms, and 50 million cubic meters of natural gas annually. The communication services of domestic operators cover the whole region.

(3) Talent advantage

Jilin Economic and Technological Development Zone currently has 38,000 senior and middle-level technical personnel and more than 100,000 skilled workers. There are currently 5 national enterprise technology centers such as the National Carbon Fiber Engineering Technology Research Center and Jilin Chemical Fiber Technology Center and 11 provincial scientific research institutions such as Jilin Fuel Ethanol Laboratory in the park, with strong research and development strength and more than 1.5 billion yuan invested in scientific and technological innovation every year. In particular, scientific research institutions such as the Research Institute and Design Institute of PetroChina Jilin Petrochemical Company are at the leading level in the field of chemical research and design in China.

(4) Location advantage

Jilin Economic and Technological Development Zone is located in the hub of the Northeast transportation trunk line, with internal and external transportation extending in all directions and obvious location advantages. The Changchun-Tumen Railway, the main railway line in Northeast China, passes through the area. There are two intermediate railway stations, nine stations and the new nine stations. The development zone also has a railway marshalling station with a daily capacity of 4,000 vehicles. The dedicated railway lines for enterprises in the area have reached 25 kilometers and railway transportation is very convenient. The development zone is 85 kilometers away from Changchun. The Changchun-Hunchun Expressway, the main trunk line of the northeast expressway network, passes through the area with an exit. There is also the Jilin-Changchun North Line. It only takes more than 40 minutes from the development zone to Changchun along the expressway and only 60 kilometers to Longjia International Airport. Air traffic is very convenient.

(5) Industrial advantage

There are about 650 enterprises directly engaged in chemical production in Jilin City, with more than 1,000 kinds of various chemical products. Most of the raw materials needed for production can be purchased nearby.

Jilin’s chemical industry has a solid foundation. Chemical production enterprises have grown to more than 500 households and more than 100 enterprises above designated size. PetroChina Jilin Petrochemical Company, Jilin Fuel Ethanol Company and Jilin Chemical Fiber Group Company occupy important positions in the same industry in China. The city’s chemical industry has a total asset of over 50 billion yuan and has more than 80 major devices, of which more than 20 devices have the highest production capacity in the country.

At present, the pharmaceutical industry in Jilin Province mainly includes the “three leading sectors” of modern traditional Chinese medicine, chemical medicine and biological medicine, and the “five potential sectors” of biological health materials and health food, medical devices, pharmaceutical testing instruments and equipment, pharmaceutical commerce and circulation, and medical health and services. The pharmaceutical health industry has become a new pillar industry.

1.2 Content and Scale of Project Construction

1.2.1 Product Scale

Annual output of 45,000 tons of coated paper products with polylactic acid.

1.2.2 Content of Project Construction

The project plans to cover an area of 40,000 square meters, purchase a PLA coated paper production device with an annual output of 45,000 tons, build a new factory building, a raw material warehouse, a technology research and development laboratory, a quality inspection line, an administrative office building, a staff warehouse and auxiliary facilities.

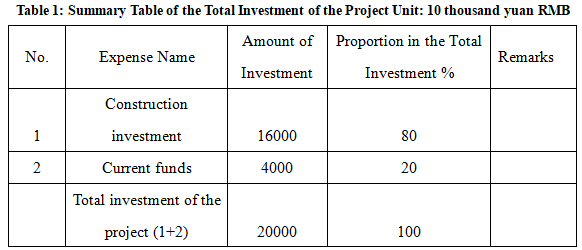

1.3 Total Investment and Fund Raising of the Project

The total investment of the project is 200 million yuan, including the construction assets investment of 160 million yuan.

1.4 Financial Analysis and Social Evaluation

1.4.1 Main Financial Indexes

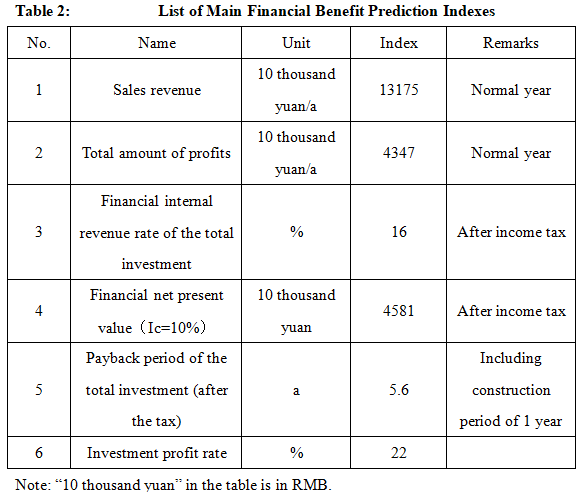

After the project is completed, its annual operating revenue will be 131.75 million yuan, its profit will be 43.47 million yuan, its investment payback period will be 5.6 years (after the tax, including the construction period of 1 year) and its investment profit rate will be 22%.

1.4.2 Social Evaluation

The production process of polylactic acid has less pollution, and the product is biodegradable to realize circulation in nature, which is an ideal green polymer material with good biodegradability. After use, it can be completely degraded by microorganisms in nature to finally generate carbon dioxide and water without polluting the environment. It is conducive to solving white pollution, reducing dependence on petroleum resources and breaking down green trade barriers in developed countries.

This project conforms to the local industrial development direction, can promote the development of related supporting industries and promote the development of regional economy. The construction of the project can bring a large amount of tax revenue to the local government and provide about 40 jobs, which has great social benefits.

1.5 Cooperative Ways

Joint venture, other methods can be discussed in person.

1.6 What to be Invested by Foreign Party

Capital, equipment, technology

1.7 Construction Site of the Project

Jilin Economic and Technological Development Zone

1.8 The On-going Condition of Project

Project cooperation plan has been prepared.

2.Introduction to Partner

2.1 Basic Conditions

Name: Bureau of Commerce of Jilin Economic and Technological Development Zone

Address: Jilin Economic and Technological Development Zone

2.2 Overview

Jilin Economic and Technological Development Zone is a national economic and technological development zone approved by the State Council and the only national patent industrialization pilot base approved by the State Intellectual Property Office in Northeast China with obtaining double authentication of ISO14001 environmental management and ISO9001 quality management system certification. The administrative area of the zone is 103 square kilometer divided into East Economic Development Zone, West Economic Development Zone and North Economic Development Zone constructed in 2017.

The planning area of Jilin Economic and Technological Development Zone is adjacent to Songhua River in the east, north Changchun-Jilin line in the west, Changchun-Hunchun Expressway in the south and Tongxi River in the north.

It is home to various kinds of 893 enterprises, including 50 industrial enterprises above designated size with a resident population of 68000, a total of 11.2 billion yuan of regional GDP, 1.47 billion yuan of fiscal revenue and 17.9 billion yuan of fixed asset investment have been obtained since the establishment of the zone. Jilin Economic and Technological Development Zone is located in the downstream of Songhua River City area and the windward area of the city with smooth terrain. It is an ideal bearing area for Jilin city to expand its urban development space and realize the “reducing the secondary industry and developing the tertiary industry” for old enterprises in the city. It is also the first choice for foreign investors to invest and build factories in the northeast of China.

The layout of Jilin Economic and Technological Development Zone is organized according to park-based cluster-type form with focus on the development of large-scale industrial projects. Five industrial parks are planned including chemical industrial park, light industrial chemical fiber textile industrial park, brand food industrial park, mechanical and electronic Industrial park, and biological energy and environmental protection industrial park according to the concept of centralized industry construction and development put forward by the municipal party committee and the municipal government relying on the existing pillar industries of Jilin City and the development zone.

Attention is paid to the development of three leading industries including chemical industry (including fine chemical industry, biochemical industry, natural gas chemical industry), light chemical fiber textile industry and brand food industry, more efforts are made for the development of energy and environmental protection industry and safety technology industry and efforts are made actively for the development of mechanical and electronic industry so as to build an industrial concentration area with advanced technology, ecological civilization, harmonious development and complete functions. Jilin Economic and Technological Development Zone has been equipped with good urban infrastructure and supporting facilities for public works, forming relatively complete conditions for industrial projects carried out in the zone and for production after eight years of development and construction. North Songjiang Road is the “lifeline” connecting the development zone and the urban area, which was opened for transportation in August 2004. Three vertical and two horizontal trunk road network have been formed in and around the zone currently, the community road is further improved, all pipelines are laid in one time, the water supply capacity is 80000 ton/day, the industrial water purification capacity is 150000 ton/day, and the sewage discharge capacity is 60000 ton/day. There are two secondary substations with power distribution capacity of 120000 KVA; a large thermal power plant and two self-contained power plants are located here which can supply 5000 tons of steam of various qualities every hour; the fixed telephone and mobile communication are provided in a synchronized manner with the urban area; the basic lighting works in the area are basically completed with the main streets lightened; the greening works are fully spread with main streets planted with trees and flowers showing a good external image.

Jilin Economic Development Zone has made great efforts to transform and upgrade traditional industries, vigorously develop strategic emerging industries, and focus on the development of modern service industries in accordance with the development direction of high-end, large-scale and clustering industries since a new round of development strategic planning has been implemented in the zone, which accelerates the growth of scale and volume, deepen the industrial chain, and significantly improve the quality and efficiency. The strength of the fine chemical industry continues to pick up with 64 affiliated enterprises of which the products covering more than 200 kinds of 78 categories realizing a comprehensive production capacity of 3 million tons and an economic volume accounting for more than 50% of the total area. The water reducing agent of Jilin Zhongxin Chemical Co., Ltd. has been exported to over 30 countries and areas making Jilin Zhongxin Chemical Co., Ltd become the water reducing agent raw material supplier for the Jakarta-Bandung high speed rail project in Indonesia. Cornell aniline ranks the first in terms of the sales volume in the world. 300000 tons of olefins have been basically completed, which will promote the overall development of more than ten affiliated enterprises effectively. New material industry cluster is accelerated with 6 backbone enterprises established successively. The zone boasts the first national carbon fiber high-tech industrialization base in China and is one of the three major industrial cluster areas in China which also contain Lianyun Port in Jiangsu Province and Weihai in Shandong Province featuring outstanding advantages in raw material supply, technology research and development, cost control and industrial matching. The annual production capacity of precursor is 15000 tons (ranking the first in China in terms of production capacity and market share) and the annual production capacity of carbon filament is 2860 tons. The terminal application field is expanding continuously, and the overall industry is developing steadily. The total amount of biological industry has doubled. The industrial chain of “bioethanol-ethylene oxide-alcohol ether” has been formed with 7 backbone enterprises set up realizing a comprehensive production capacity of 1.15 million tons and a tax contribution of more than 30% of the zone. The output of fuel ethanol is the largest in Asia currently and is increasing to reach one million tons; the capacity of ethylene oxide can reach 180000 tons so that the bottleneck of raw material shortage can be effectively handled. The momentum of development of pharmaceutical industry is strong with 6 key enterprises set up of which products cover active pharmaceutical ingredients, pharmaceutical intermediates, bio-pharmaceuticals, Chinese and Western patent medicines and other categories with a comprehensive capacity of 20000 tons. Jilin Wanhua Fine Chemical Co., Ltd. has realized production capacity with efficiency. 150 tons of pharmaceutical intermediates of Sihuanshuang and active pharmaceutical ingredient of Jilin kangnaier Shengye API Co., Ltd have been basically completed. 20000 tons of taurine have been under construction. The market share of new drugs of Jilin Jinheng Pharmaceutical Co., Ltd has been greatly increased with the production capacity of vitamin E ranking the third in the world.

2.3 Contact Method:

Contact Person: Ren Tao

Tel: 18504327576

E-mail: 281321733@qq.com

Contact Method of Project City (Prefecture):

Contact Organization: Investment Promotion Service Center of Jilin Cooperation and Exchange Office

Contact Person: Liu Kai

Contact Tel: 15981169997